Recent Posts

-

Zhong Xiang Rubber’s 2025 Outdoor Team-Building Event Was a Complete Success!

Zhong Xiang Rubber’s 2025 Outdoor Team-Building Event Was a Complete Success!

08/25/2025

-

ZHONG XIANG RUBBER Invites You to BAUMA 2025 Munich | Pioneering Vibration Solutions for Construction Machinery

ZHONG XIANG RUBBER Invites You to BAUMA 2025 Munich | Pioneering Vibration Solutions for Construction

03/31/2025

-

Uniting Hearts and Efforts, Creating Great Achievements

In mid-2024, the business team of ZHONG XIANG RUBBER held a captivating team-building event themed "Uniting Hearts and Efforts, Creating Great Achievements."

07/29/2024

-

Celebrating the Strength and Grace of Women at ZHONG XIANG RUBBER

Today, on International Women's Day, we take a moment to honor and celebrate the remarkable women of ZHONG XIANG RUBBER. These incredible individuals are not just a part of our workforce; they are the backbone of our innovation, the heart of our operations, and the soul of our corporate culture.

03/09/2024

-

ZHONG XIANG RUBBER Celebrates Successful Participation in 2024 WORLD DEFENSE SHOW in Saudi Arabia

ZHONG XIANG RUBBER, as leading player in the vibration & noise solutions industry, proudly announces its successful participation in the 2024 WORLD DEFENSE SHOW (2024WDS) held in Saudi Arabia.

02/27/2024

-

Join us at the World Defense Show in Saudi Arabia

We are thrilled to announce our participation in the upcoming 2024 World Defense Show (2024 WDS) in Saudi Arabia! Zhong Xiang Rubber Products Co., Ltd. is excited to showcase our state-of-the-art Vibration & Noise Solutions tailored for the defense industry.

01/08/2024

-

What partnerships that Zhong Xiang rubber provided to industrial machinery companies and helped them increase their overall effectiveness?

What partnerships that Zhong Xiang rubber provided to industrial machinery companies and helped them increase their overall effectiveness?

12/11/2023

-

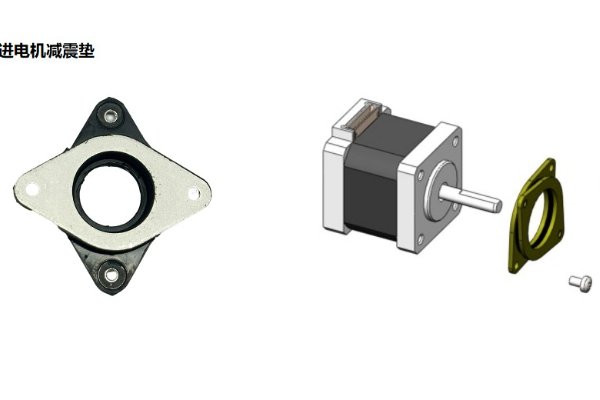

ZHONG XIANG RUBBER successfully put into production Step motor damper

The Anti-Vibration Mount designed specifically for Step Motors. Engineered with cutting-edge technology, this product stands as a formidable damper, ensuring optimal performance used on step motors.

12/07/2023

-

Strengthening Safety Awareness and Promoting Safe Production

On September 14, 2023, Zhong Xiang Rubber successfully held a fire drill with the theme "Strengthening Safety Awareness and Promoting Safe Production". The drill aimed to enhance employees' awareness of fire safety and emphasize the importance of safe production.

09/15/2023

-

High-Quality Rubber to metal boned - Zhong Xiang Rubber Products Co. Provides Superior Performance and Reliability

Look no further than Zhong Xiang Rubber Products Co. Our company in designing and manufacturing exceptional rubber-to-metal bonded components to help your equipment and machinery maintain stability and smooth operation in various environmental conditions.

09/13/2023

How to protect your Air Compressors with rubber isolate mounts?

A compressed air setup consists of motors, air compressors, machines running on compressed air, and metal piping that connects these different components.An air compressor provides compressed air to power a variety of machines in an industrial setup. During the operation of air compressors, vibrations of different frequencies are generated, which can damage the piping and other connected structures.

The harmonics of vibrations produced in the air compressor chamber are different than the harmonics of vibrations produced in the piping carrying the compressed air or the machines utilizing the compressed air. When vibrations from one source are transmitted to the connected structures, the overlap of vibrations of varied frequencies can lead to major damage to piping over a period of continuous use. This could cause leakage from the pipes resulting in a dip in the performance of air compressors and connected equipment.

The base of the compressor container, supported by metallic legs, is also highly susceptible to vibrations. After long periods of constant usage, the vibrations can damage the weld that connects the base of the compressor with the legs.

Installing rubber isolator mounts is one of the most economical ways to control vibrations from damaging the piping connecting the air compressor to the machine. Rubber mounts minimize connect between the metallic parts and absorb vibrations from being transmitted to supporting structures. Thus, the vibrations produced in the air compressor don’t affect the piping’s structural stability.

How to protect your air compressor setup with rubber isolate mounts? If you need help in this case, please contact us for more information, ZXRUBBER offers a whole range of vibration solutions to safeguard your critical equipment.