Recent Posts

-

Zhong Xiang Rubber’s 2025 Outdoor Team-Building Event Was a Complete Success!

Zhong Xiang Rubber’s 2025 Outdoor Team-Building Event Was a Complete Success!

08/25/2025

-

ZHONG XIANG RUBBER Invites You to BAUMA 2025 Munich | Pioneering Vibration Solutions for Construction Machinery

ZHONG XIANG RUBBER Invites You to BAUMA 2025 Munich | Pioneering Vibration Solutions for Construction

03/31/2025

-

Uniting Hearts and Efforts, Creating Great Achievements

In mid-2024, the business team of ZHONG XIANG RUBBER held a captivating team-building event themed "Uniting Hearts and Efforts, Creating Great Achievements."

07/29/2024

-

Celebrating the Strength and Grace of Women at ZHONG XIANG RUBBER

Today, on International Women's Day, we take a moment to honor and celebrate the remarkable women of ZHONG XIANG RUBBER. These incredible individuals are not just a part of our workforce; they are the backbone of our innovation, the heart of our operations, and the soul of our corporate culture.

03/09/2024

-

ZHONG XIANG RUBBER Celebrates Successful Participation in 2024 WORLD DEFENSE SHOW in Saudi Arabia

ZHONG XIANG RUBBER, as leading player in the vibration & noise solutions industry, proudly announces its successful participation in the 2024 WORLD DEFENSE SHOW (2024WDS) held in Saudi Arabia.

02/27/2024

-

Join us at the World Defense Show in Saudi Arabia

We are thrilled to announce our participation in the upcoming 2024 World Defense Show (2024 WDS) in Saudi Arabia! Zhong Xiang Rubber Products Co., Ltd. is excited to showcase our state-of-the-art Vibration & Noise Solutions tailored for the defense industry.

01/08/2024

-

What partnerships that Zhong Xiang rubber provided to industrial machinery companies and helped them increase their overall effectiveness?

What partnerships that Zhong Xiang rubber provided to industrial machinery companies and helped them increase their overall effectiveness?

12/11/2023

-

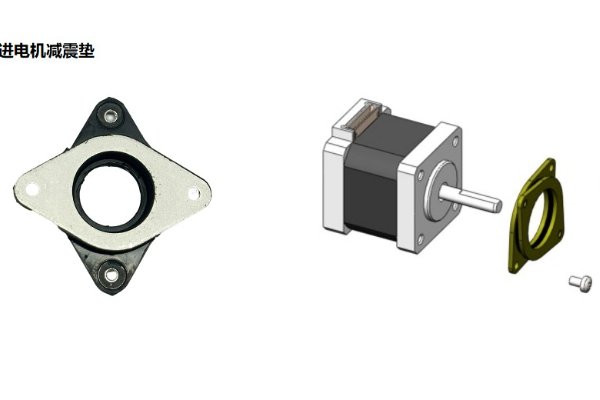

ZHONG XIANG RUBBER successfully put into production Step motor damper

The Anti-Vibration Mount designed specifically for Step Motors. Engineered with cutting-edge technology, this product stands as a formidable damper, ensuring optimal performance used on step motors.

12/07/2023

-

Strengthening Safety Awareness and Promoting Safe Production

On September 14, 2023, Zhong Xiang Rubber successfully held a fire drill with the theme "Strengthening Safety Awareness and Promoting Safe Production". The drill aimed to enhance employees' awareness of fire safety and emphasize the importance of safe production.

09/15/2023

-

High-Quality Rubber to metal boned - Zhong Xiang Rubber Products Co. Provides Superior Performance and Reliability

Look no further than Zhong Xiang Rubber Products Co. Our company in designing and manufacturing exceptional rubber-to-metal bonded components to help your equipment and machinery maintain stability and smooth operation in various environmental conditions.

09/13/2023

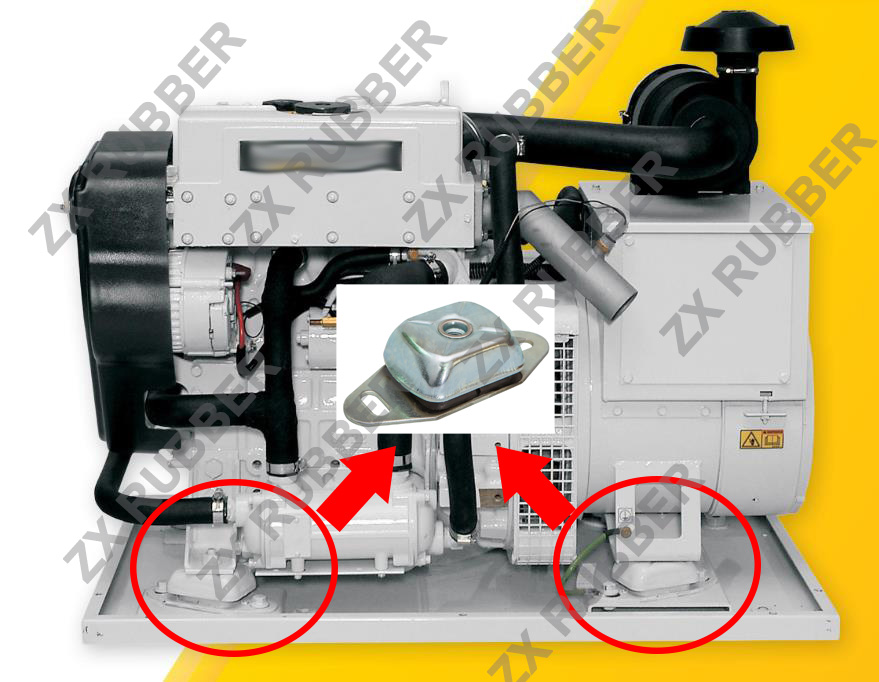

MARINE engine mounts

Rubber mounts are an essential component of marine engines, used to support and dampen the vibrations caused by the engine's operation. They are designed to absorb the engine's movement and prevent it from transmitting vibrations and noise to the boat's structure and passengers. Rubber mounts are widely used in marine engines because they offer excellent vibration isolation, are durable and resistant to corrosion, and are cost-effective.

Zhongxiang Rubber supplies several different types of rubber mounts available for marine engines, including shear mounts, cylindrical mounts, and sandwich mounts. Shear mounts are typically used in smaller marine engines and consist of a rubber block that is bonded to a metal plate on both sides. Our special design and deep understanding to anti-vibration provide excellent shear resistance and are ideal for applications where the engine is subjected to high levels of lateral force. Cylindrical mounts, on the other hand, are used in larger marine engines and consist of a cylindrical rubber element that is bonded to a metal plate on one end. This design provides excellent isolation against vertical and horizontal vibrations. Sandwich mounts are a combination of shear and cylindrical mounts, and are used in applications where both types of vibration isolation are required.

One of the main advantages of Zhongxiang Ruber anti-vibration mounts is that they are very effective at isolating vibrations from the engine to the boat's structure. This is important because excessive vibration can cause damage to the boat's hull, deck, and other components, and can also make the ride uncomfortable for passengers. By isolating the engine's vibrations, rubber mounts help to ensure that the boat is more stable, smoother, and quieter.

Another advantage of rubber mounts is their durability and resistance to corrosion. Zhongxiang Rubber use all top quality material. Our marine engines are exposed to a harsh environment that includes saltwater, moisture, and other corrosive elements. They are typically made from materials that are resistant to corrosion, such as neoprene or natural rubber, and are designed to withstand the rigors of marine use.