Recent Posts

-

Uniting Hearts and Efforts, Creating Great Achievements

In mid-2024, the business team of ZHONG XIANG RUBBER held a captivating team-building event themed "Uniting Hearts and Efforts, Creating Great Achievements."

07/29/2024

-

ZHONG XIANG RUBBER Invites You to BAUMA 2025 Munich | Pioneering Vibration Solutions for Construction Machinery

ZHONG XIANG RUBBER Invites You to BAUMA 2025 Munich | Pioneering Vibration Solutions for Construction

03/31/2025

-

Celebrating the Strength and Grace of Women at ZHONG XIANG RUBBER

Today, on International Women's Day, we take a moment to honor and celebrate the remarkable women of ZHONG XIANG RUBBER. These incredible individuals are not just a part of our workforce; they are the backbone of our innovation, the heart of our operations, and the soul of our corporate culture.

03/09/2024

-

ZHONG XIANG RUBBER Celebrates Successful Participation in 2024 WORLD DEFENSE SHOW in Saudi Arabia

ZHONG XIANG RUBBER, as leading player in the vibration & noise solutions industry, proudly announces its successful participation in the 2024 WORLD DEFENSE SHOW (2024WDS) held in Saudi Arabia.

02/27/2024

-

Join us at the World Defense Show in Saudi Arabia

We are thrilled to announce our participation in the upcoming 2024 World Defense Show (2024 WDS) in Saudi Arabia! Zhong Xiang Rubber Products Co., Ltd. is excited to showcase our state-of-the-art Vibration & Noise Solutions tailored for the defense industry.

01/08/2024

-

What partnerships that Zhong Xiang rubber provided to industrial machinery companies and helped them increase their overall effectiveness?

What partnerships that Zhong Xiang rubber provided to industrial machinery companies and helped them increase their overall effectiveness?

12/11/2023

-

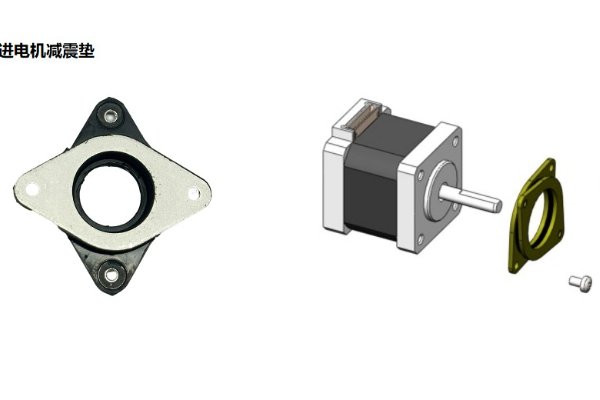

ZHONG XIANG RUBBER successfully put into production Step motor damper

The Anti-Vibration Mount designed specifically for Step Motors. Engineered with cutting-edge technology, this product stands as a formidable damper, ensuring optimal performance used on step motors.

12/07/2023

-

Strengthening Safety Awareness and Promoting Safe Production

On September 14, 2023, Zhong Xiang Rubber successfully held a fire drill with the theme "Strengthening Safety Awareness and Promoting Safe Production". The drill aimed to enhance employees' awareness of fire safety and emphasize the importance of safe production.

09/15/2023

-

High-Quality Rubber to metal boned - Zhong Xiang Rubber Products Co. Provides Superior Performance and Reliability

Look no further than Zhong Xiang Rubber Products Co. Our company in designing and manufacturing exceptional rubber-to-metal bonded components to help your equipment and machinery maintain stability and smooth operation in various environmental conditions.

09/13/2023

-

Check out the brand new sample showroom of Zhong Xiang Rubber Co

Check out the brand new sample showroom of Zhong Xiang Rubber Co., , displaying over a thousand standard shockproof parts and a wide range of independently developed shockproof products.

09/01/2023

Material properties

NR - Natural Rubber

Milk-white liquid in the bark of rubber tree is named as "Latex". Rubber is obtained from 30-40% part of the collected liquid. Natural rubber's structure becomes smoothed under load and tension. Natural rubber has a regular structure. Even if there is no strengthening filling materials in its structure, tensile strength values are high.

Operation Temperature: -60°C / +90°C

Physical Properties:

High Tensile Strength

High Tear Strength

High Raw Rubber Resistance

Superior Elasticity Property

Superior Dynamic Properties

High Permanent Deformation Values

Usage Environments:

Watery Environments in Temperatures Which Are Not High

Glycol Based Oils

Usage Fields:

Mechanical Parts

Vibration and Impact Damping Parts

Bushings

Vibration Damping Connections

Parts for Motors

Shoe Sole

Hoses

Conveyor Bants

Ground Coating

Sponge

Glues

SBR - Styrene Butadiene Rubber

It is the low-cost rubber type which is most used worldwide. Structure of the mixture is irreguar. Can be used instead of natural rubber.

Operation Temperature: -50°C / +100°C

Physical Properties:

Easy to Process

Operation Time is Short

Suitable for Extrusion

Poor Elasticity Property

High Abrasion Properties

High Aging Properties

Usage Environments:

Solvent Chemicals

Glycol Based Brake Oils

Bases

Usage Fields:

Wehicle Tyres

Light-Colored Technical Parts

Extrusion Materials

Cable and Electricity Materials

Brake and Clutch Pads

Transparent Bands

Adhesive

Dynamic Parts (V Belts)

EPDM - Ethylene Propylene Diene Rubber

Resistance to heat, light and oxidation is perfect. It is used in production of lightweight materials as it has low density. Gives the possibility to make cost effective mixtures. Can be used in extrusion. Resistant to aging at heat . Flexibility at low temperature is good.

Operation Temperature: -40°C / +150°C

Usage Environments:

Watery and Concentrated Acids

Alkalis

Phosphate Ester-Based Flame Proof Hydraulic Liquids

Liquids Silicone

Warm Water and Steam

Usage Fields:

Insulation Materials for High Voltage Cables

Doors and Glass Sealing Parts

Radiator and Heating Hoses

Bellows and Gaskests for White Goods and Automotive

Conveyor Belts

Tank Undercoat Coating (for Water and Chemical Storages)

NBR - Nitril Rubber

Created as the result of mixing acrylonitrile and butadiene monomers with the help of additives. Acrylonitrile rate in the mixture determines the material properties. Generally, acrylonitrile rate in the mixture changes between 18% and 50%. Acrylonitrile, gives the mixture polar property and prevents dissolution against hydrocarbons.

As the acrylonitrile rate in the mixture increases, below mentioned properties are improved: Density, Hardness, Burning speed, Mixture processability, Mechanical properties, Elasticity, Permanent continuance, Aging, Resistance to fatigue, Abrasion resistance, Life values.

As the acrylonitrile rate in the mixture increases, Material's resistance increases against the following materials: Oils, Fuels, Lubricant materials, Greases, Gases. As the acrylonitrile rate in the mixture reduces, below mentioned properties worsen. Resistance of material at low temperatures, Permanent deformation values, Elasticity, Production conditions.

Operation Temperature: -40°C / +100°C

Usage Fields:

Sealing Elements

Coupling, Membrane, Fuel, Oil and Hydrolic Hoses

Pneumatic Hoses

Connection Elements

Conveyor Belts

Cylinder Coating

Worker Clothes and Boots

Rubber Cliche and Stamps

VMQ - Silicon Rubber

On contrary to polymer rubbers, it consists of Silicium and Oxygen bond systems. Although the strengths between the bonds are weak, it has a stabile structure. Occured bond structures are expressed with "Q" letter. Their namings show variety, according to the auxiliary material used during the preparation. Silicone Rubber Mixture; If prepared by using Methyl (CH-Saturated Hydrocarbon)-MQ, If prepared by using Methyl Vinyl (Saturated and Unsaturated Hydrocarbon)-VMQ, If prepared by using Phenyl Methyl (Organic Hydrocarbon and Saturated Hydrocarbon)-PMQ letters are used to express.

Operation Temperature: -50°C / +200°C

Usage Environments:

Strong Resistance to Ultraviolet Light Outstanding Ozone Resistance

Resistant to External Influences

Air and Moisture Resistant

Good Insulation Properties

Fire Resistant

Resistant to Aging

Long Life

Durable Underground

Can Be Produced Transparently

Elasticity Property is Very Good

Easily Paintable

Not Poisonous

Physiologically Harmless

An Expensive Material

Usage Fields:

Cable, Cable Ends, Insulators and Buttons Spark Plug Cables and Caps

Radiator Hoses and Sealing Elements

Insulated Diaphrams for Brakes

Baby Pacifiers

Gas Masks

Impermeability Gaskets for Oven Systems

Impermeability Gaskets for Cooler Cupboards

Impermeability Gaskets for Ozone Systems

FKM - Fluoro Elastomer Rubber

Polar and saturation properties are superior. Resistant to high temperatures. Inflation property is low. Resistant to burning. Flame proof. Gas impermeability is low. Processing is hard. An expensive rubber material. Contact with food materials is not suitable. Resistant to oxygen and ozone.

Operation Temperature: -30°C / +250°C

Usage Environments:

Aromatic Hydrocarbons

Fuels

Oils

Greases

Acids

Petroleum Oils

Solvents

Usage Fields:

Aviation and Space Industry

Automotive Industry

Cylinder Coating

HNBR - Hydrogene Nitrile Rubber

HNBR, showing great resistance to engine oil, acidic gases, aminic oils, oxidized fuels and machine greases, provides us a high tensile strength if required, during the high-temperature working conditions of NBR, EPDM and FKM. Fully saturated NBR can build cross-links with peroxides. Those peroxide cross-links that are formed along the double-bonding, raise thermal stability and oxidation balance. Vulcanisate Compounds provide the highest resistance to hot air and hot oil, oxidatives and ozone separation, sulphurios oils, including hydrogenated sulphide, oil additives including nitrogene and sulphur and industrial chemicals. HNBR is known for its high physical strength and advanced tear resistance.

Operation Temperature: -30°C / +150°C

ACM - Polyacrylic Rubber

ACM is a copolymerization of acrylic esters and monomers. The acrylic esters used in ACM are ethyl acrylates and/or butyl and oktyl acrylate, ethyl methoxi, or ethyloxi acrylates. These copolymeres are highly resistant to oil, heat, aging and ozone. Tensile strength of Acrylic rubbers are not as good as NR and NBR. Especially new generation ACMs can work at 150-1600C around 1000 hours. But, at high temperatures they tend to soften. ACM Vulcanisates are more resistant to expansion when exposed to animal fat, vegetable oil and mineral oil, then other rubber compounds except FKM, which decreases as temperature rises. ACM does not well with chemicals. Dry working conditions are bad, and not suitable for working under low temperatures and in water. More then 90% of ACM Manufacture are used in automotive industry. It is used usually in crankhafts, automatic and differential transmissions as shaft rubber and also in o-rings, valves and oil hoses. Its high price usually shadows its other properties and mostly FKM(Fluoroelastomers) is preferred instead.

Operation Temperature: +160°C / +170°C

CR - Chloroprene Rubber

Polar properties are good. It is very resistant to oil and burning. It has low gas permeability. Adhesion to textile and metal materials is strong. Wear resistance is very good. It has superior mechanical properties.

Operation Temperature: -20°C / +120°C

Physical Properties:

Resistant to oils

Resistant to air and ozone

Resistant to water

Resistant to chemicals

Resistant to acids

Usage Fields:

Parts with risk of burning

V straps

Rubber bellows

Vibration damping elements

Diving suits

High-pressure hydraulic and brake hoses

Containers