Recent Posts

-

Zhong Xiang Rubber’s 2025 Outdoor Team-Building Event Was a Complete Success!

Zhong Xiang Rubber’s 2025 Outdoor Team-Building Event Was a Complete Success!

08/25/2025

-

ZHONG XIANG RUBBER Invites You to BAUMA 2025 Munich | Pioneering Vibration Solutions for Construction Machinery

ZHONG XIANG RUBBER Invites You to BAUMA 2025 Munich | Pioneering Vibration Solutions for Construction

03/31/2025

-

Uniting Hearts and Efforts, Creating Great Achievements

In mid-2024, the business team of ZHONG XIANG RUBBER held a captivating team-building event themed "Uniting Hearts and Efforts, Creating Great Achievements."

07/29/2024

-

Celebrating the Strength and Grace of Women at ZHONG XIANG RUBBER

Today, on International Women's Day, we take a moment to honor and celebrate the remarkable women of ZHONG XIANG RUBBER. These incredible individuals are not just a part of our workforce; they are the backbone of our innovation, the heart of our operations, and the soul of our corporate culture.

03/09/2024

-

ZHONG XIANG RUBBER Celebrates Successful Participation in 2024 WORLD DEFENSE SHOW in Saudi Arabia

ZHONG XIANG RUBBER, as leading player in the vibration & noise solutions industry, proudly announces its successful participation in the 2024 WORLD DEFENSE SHOW (2024WDS) held in Saudi Arabia.

02/27/2024

-

Join us at the World Defense Show in Saudi Arabia

We are thrilled to announce our participation in the upcoming 2024 World Defense Show (2024 WDS) in Saudi Arabia! Zhong Xiang Rubber Products Co., Ltd. is excited to showcase our state-of-the-art Vibration & Noise Solutions tailored for the defense industry.

01/08/2024

-

What partnerships that Zhong Xiang rubber provided to industrial machinery companies and helped them increase their overall effectiveness?

What partnerships that Zhong Xiang rubber provided to industrial machinery companies and helped them increase their overall effectiveness?

12/11/2023

-

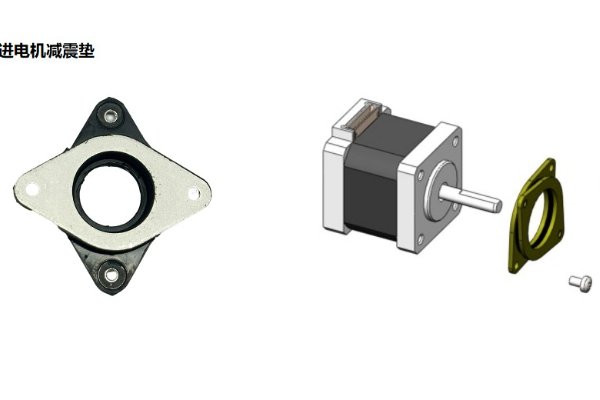

ZHONG XIANG RUBBER successfully put into production Step motor damper

The Anti-Vibration Mount designed specifically for Step Motors. Engineered with cutting-edge technology, this product stands as a formidable damper, ensuring optimal performance used on step motors.

12/07/2023

-

Strengthening Safety Awareness and Promoting Safe Production

On September 14, 2023, Zhong Xiang Rubber successfully held a fire drill with the theme "Strengthening Safety Awareness and Promoting Safe Production". The drill aimed to enhance employees' awareness of fire safety and emphasize the importance of safe production.

09/15/2023

-

High-Quality Rubber to metal boned - Zhong Xiang Rubber Products Co. Provides Superior Performance and Reliability

Look no further than Zhong Xiang Rubber Products Co. Our company in designing and manufacturing exceptional rubber-to-metal bonded components to help your equipment and machinery maintain stability and smooth operation in various environmental conditions.

09/13/2023

Rubber injection Advantage

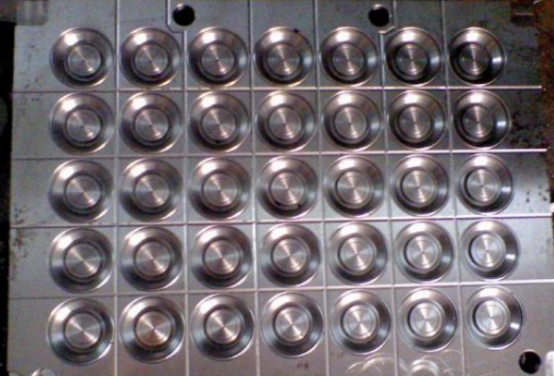

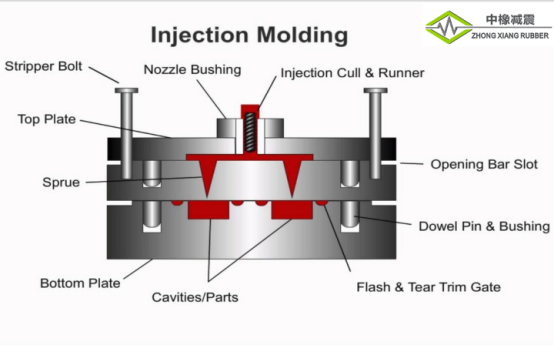

Rubber injection molding and rubber compression molding are two popular methods used for the production of rubber parts. While both methods have their advantages and disadvantages, rubber injection molding is often preferred over rubber compression molding for several reasons. That’s why we Zhongxiang Rubber uses rubber injection for all products.

One of the main advantages of rubber injection molding is the precision and repeatability it offers. The process involves injecting rubber material into a closed mold cavity under high pressure, which allows for consistent and accurate production of parts with tight tolerances. This makes it an ideal process for the production of parts with complex geometries or tight dimensional requirements. In contrast, rubber compression molding relies on the compression of the rubber material within a mold, which can result in more variation in part dimensions and tolerances.

Another advantage of rubber injection molding is the reduced cycle times. The process involves preheating the rubber material before injection, which reduces the time required for curing and cooling. This allows for faster production cycles, leading to higher productivity and lower production costs. In contrast, rubber compression molding requires a longer curing time, which can increase production costs and reduce productivity.

In addition, rubber injection molding allows for better material utilization and reduced waste compared to rubber compression molding. The injection process ensures that the material is distributed evenly throughout the mold, minimizing the chances of air pockets or other defects that may lead to scrap. This results in a higher yield of usable parts and less material waste. In contrast, rubber compression molding can result in more scrap due to uneven material distribution within the mold.

Rubber injection molding also allows for the use of a wider range of materials. The injection process allows for better control over the temperature and pressure, which allows for the use of materials with higher viscosity or those that require higher curing temperatures. This makes it possible to produce parts with a wide range of mechanical properties, including high strength, abrasion resistance, and flexibility. In contrast, rubber compression molding may be limited to materials with lower viscosity and lower curing temperatures.

Overall, rubber injection molding offers several advantages over rubber compression molding. It provides greater precision, faster cycle times, better material utilization, and a wider range of materials. These benefits make it an ideal choice for the production of high-quality rubber parts. However, rubber compression molding may still be preferred for certain applications, such as those requiring lower production volumes or lower tooling costs.

Zhongxiang Rubber Products Co., Ltd has 20 sets of high-precision rubber injection machines of latest technology. This enable we earn good reputation for top qualilty from customers through out the world.